Introduction

In the modern era of manufacturing, the integration of artificial intelligence (AI) and robotics is reshaping how production lines operate. Some of the world’s leading manufacturing companies are experimenting with AI-driven production systems to not only boost output and precision but also minimize human error, which has historically been one of the largest sources of inefficiency and defects in manufacturing processes. The ongoing shift towards Industry 4.0, characterized by smarter factories and interconnected devices, promises to create a more efficient, flexible, and accurate manufacturing environment.

By combining robotics, AI, machine learning, and advanced sensors, manufacturers can create autonomous production lines capable of performing tasks faster and with higher consistency than human workers. Moreover, these systems can continuously monitor and adapt to operational conditions, optimizing workflows and identifying potential issues before they escalate into significant problems.

This article delves into the emerging trend of AI-driven production lines in the manufacturing sector, examining how leading companies are utilizing this technology to achieve greater productivity, accuracy, and reliability. We will also discuss the potential challenges and opportunities these innovations present, and the transformative effects they are having on the industry.

1. The Rise of AI-Driven Manufacturing

1.1 The Evolution of Automation in Manufacturing

Automation has been a core component of manufacturing for decades, starting with simple mechanical devices and later evolving into more complex systems driven by computers and programmable logic controllers (PLCs). The advent of robotics further expanded automation’s role, allowing machines to take over repetitive tasks, resulting in improved efficiency, speed, and reduced labor costs.

However, the integration of AI is taking automation to the next level. AI introduces the ability for machines to not only follow pre-programmed instructions but also learn from data, making intelligent decisions based on real-time feedback. This capability allows production lines to become adaptive, self-correcting, and optimized without the need for direct human intervention.

1.2 Industry 4.0: The Intersection of AI, Robotics, and IoT

Industry 4.0 represents the fourth industrial revolution, characterized by the convergence of cyber-physical systems, Internet of Things (IoT), cloud computing, and AI. In manufacturing, this revolution has led to the creation of smart factories that leverage real-time data to improve every aspect of production, from planning and scheduling to maintenance and product quality control.

AI-driven production lines are a cornerstone of Industry 4.0, enabling factories to implement predictive maintenance, optimize workflows, and enhance product customization. With the proliferation of connected devices and sensors, AI can also analyze vast amounts of data from machines, operators, and the environment to identify inefficiencies, bottlenecks, and opportunities for improvement.

2. Key Benefits of AI-Driven Production Lines

2.1 Improved Production Efficiency and Throughput

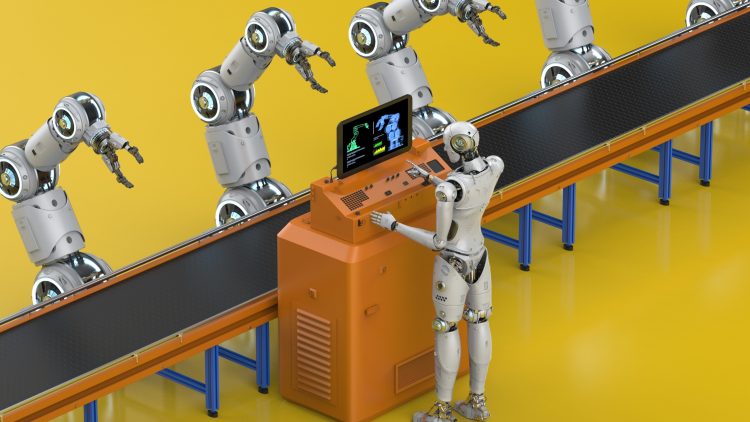

One of the most significant advantages of AI in manufacturing is the enhancement of production efficiency. Traditional production lines often rely on human operators to perform repetitive tasks, which can lead to slowdowns, inconsistencies, and increased downtime. AI-powered robots, on the other hand, can work continuously without fatigue, maintaining consistent performance and operating at optimal speeds.

For instance, robots equipped with AI can adjust their movements in real-time, optimizing the pace of production based on current conditions. This flexibility allows manufacturers to achieve higher throughput and meet customer demands more effectively.

2.2 Enhanced Accuracy and Precision

AI-powered systems can achieve a level of accuracy and precision that is difficult for human workers to match. Whether it’s in assembly, inspection, or quality control, AI systems can perform tasks with an incredibly high degree of consistency, ensuring that every product meets the desired specifications.

For example, in automotive manufacturing, AI-driven robots are used to weld and assemble parts with pinpoint precision, reducing the risk of defects and improving the overall quality of the finished product. Similarly, AI systems used in 3D printing are capable of creating complex parts with high accuracy, allowing for the production of customized products at scale.

2.3 Reduction of Human Error

Human error has long been a significant source of defects and inefficiencies in manufacturing. Whether it’s a worker missing a step in the assembly process or failing to identify a faulty component during inspection, mistakes can lead to costly delays and product recalls.

AI-driven production lines mitigate this risk by relying on machines that do not experience fatigue, distraction, or error. Through machine learning, AI systems can continuously refine their processes, improving performance over time and eliminating the likelihood of human mistakes.

In addition, AI systems can predict potential issues, such as equipment failure, before they happen. For example, AI-enabled predictive maintenance allows machines to self-monitor their performance and alert operators about the need for repairs or adjustments, reducing the chance of catastrophic breakdowns and minimizing downtime.

2.4 Cost Savings

The automation of manufacturing processes through AI and robotics can lead to significant cost savings. By reducing the reliance on human labor, manufacturers can lower wages, training costs, and the risk of workplace injuries. Moreover, AI-driven systems can optimize resource allocation, ensuring that materials, energy, and time are used efficiently.

In some cases, the use of AI has led to the creation of cobots (collaborative robots) that work alongside human operators, complementing their efforts while maintaining a focus on efficiency. This reduces the need for large-scale human labor in dangerous or monotonous tasks, leading to a safer and more cost-effective work environment.

3. Applications of AI-Driven Production Lines

3.1 Automotive Industry

The automotive industry has been at the forefront of adopting AI-driven manufacturing processes. Leading companies like BMW, Tesla, and Toyota are using AI-powered robots for tasks ranging from welding and painting to assembly and quality inspection.

AI-driven robots are particularly effective in performing repetitive, high-precision tasks such as aligning and assembling parts in the car body. In addition, AI systems are used for predictive maintenance, where machine learning algorithms analyze data from sensors embedded in production machinery to predict failures before they occur. This helps companies maintain a consistent level of productivity while reducing downtime and costs.

3.2 Electronics Manufacturing

In electronics manufacturing, where component miniaturization and complex assembly processes are required, AI-powered systems are enabling the creation of highly accurate and efficient production lines. Robots equipped with advanced vision systems can inspect and assemble tiny electronic components with incredible precision, ensuring high-quality products.

AI is also used to monitor soldering and assembly processes, ensuring that each step is performed with exacting precision. This reduces defects, increases yields, and speeds up production times for electronic devices such as smartphones, computers, and televisions.

3.3 Consumer Goods and Packaging

Manufacturers of consumer goods are also leveraging AI-driven production lines to enhance productivity and reduce errors. In packaging, for example, AI systems can automatically detect and correct defects in packaging materials, ensuring that each product is properly sealed and labeled.

AI-powered robots are also used in warehouse management and logistics, where they can sort and move products more efficiently than human workers. Automated picking and packing systems, powered by AI, help optimize the supply chain and ensure faster delivery times.

4. Challenges of AI-Driven Manufacturing

4.1 High Initial Investment

The implementation of AI-driven production lines often requires a substantial initial investment in robotics, AI software, and infrastructure. For many small to medium-sized manufacturers, the high upfront costs may be a barrier to adoption. However, as technology continues to improve and prices decrease, more companies are likely to integrate AI into their operations.

4.2 Workforce Displacement

While AI and robotics offer numerous benefits, the automation of production lines can lead to job displacement for workers whose tasks are taken over by machines. This can create challenges for workers who may need to reskill or transition to new roles within the company.

To address this issue, companies can invest in retraining programs that help workers learn new skills relevant to the evolving manufacturing landscape. Additionally, AI and robots can be used in collaboration with human workers rather than replacing them entirely, creating opportunities for employees to focus on higher-value tasks.

4.3 Integration and Adaptation

Integrating AI-driven production lines into existing manufacturing environments can be complex. Companies must ensure that new technologies are compatible with legacy systems and workflows. Additionally, adapting to AI-driven systems may require changes in business processes, which can be time-consuming and costly.

However, as the benefits of AI become more evident, manufacturers are increasingly willing to make these changes, recognizing the long-term gains in efficiency and competitiveness.

5. The Future of AI-Driven Production Lines

5.1 Continuous Evolution of AI and Robotics

As AI technology continues to evolve, so too will its role in manufacturing. Future AI-driven production lines are likely to be even more autonomous, with machines capable of performing a wider variety of tasks without human supervision. The integration of 5G networks will further enhance the capabilities of these systems by enabling real-time communication and data exchange between machines, suppliers, and manufacturers.

5.2 The Emergence of Smart Factories

The future of manufacturing is a world of smart factories, where AI, IoT, and robotics work seamlessly together to create adaptive, efficient, and flexible production environments. These factories will be able to respond to changing market demands, optimize production in real-time, and create highly customized products on demand.

Conclusion

AI-driven production lines are already transforming manufacturing, offering significant improvements in productivity, accuracy, and cost efficiency. While the technology is still evolving, its potential to reshape industries from automotive to consumer goods is undeniable. As more companies embrace automation and AI, the future of manufacturing will be one where intelligence and flexibility define the very fabric of production.

By embracing AI, manufacturers not only reduce human error and increase output but also position themselves at the cutting edge of innovation. The next generation of AI-powered production lines will be integral in the race to remain competitive in a rapidly changing global marketplace.